Business Case Study

Transform Your Manufacturing Operations Using AI Agents by Agentforce

Salesforce

Salesforce Development Salesforce Implementation Salesforce Integration AppExchange App Development Salesforce Consulting Hire a Salesforce Developer Salesforce Managed Services Salesforce Data and AIServiceNow

ServiceNow Consulting ServicesServiceNow Implementation ServicesServiceNow Managed ServicesDownload E-Guide

Download E-Guide

Register to read the complete guide as PDF on your email.

Download Customer Success Story

Download Customer Success Story

Submit your details below to get a detailed success story delivered to your inbox as a PDF.

Download Case Study

Download Case Study

Register to read the complete solution and benefits of this Case Study as a PDF on your email.

Download Whitepaper

Download Whitepaper

Register to Get the Whitepaper Delivered Straight to Your Email.

Download Industry Report

Download Industry Report

Register to Get the Industry Report Delivered Straight to Your Email.

Table of Contents

Are you facing a hard time adjusting to a rapidly evolving manufacturing landscape? With increasing customer expectations, volatile market conditions, and global supply chain disruptions, manufacturers must navigate a host of challenges to stay ahead.

Traditional methods and manual processes are no longer sufficient to overcome these challenges and help the manufacturing industry to thrive.

Imagine a scenario where manufacturers have a clear view of their entire customer portfolio, effortlessly managing relationships and service lifecycles. Sales and operations seamlessly work together, sharing real-time information and insights to make informed decisions and drive predictable business growth. Suppliers, partners, and customers are all connected on a unified platform, promoting transparency and collaboration across the entire ecosystem.

Salesforce Manufacturing Cloud is a comprehensive CRM solution designed specifically for manufacturing. It revolutionizes how companies operate, transforming outdated processes and ushering in a new era of efficiency, collaboration, and customer-centricity.

In this blog, we will explore the capabilities and benefits of Salesforce Manufacturing Cloud. We will delve into how this groundbreaking solution streamlines operations, enhances collaboration, and provides actionable insights to drive growth and customer satisfaction.

Manufacturing Cloud, in simple terms, is a comprehensive customer relationship management (CRM) solution tailored specifically for the manufacturing industry.

It empowers manufacturers to efficiently handle their customer interactions and manage the entire customer service lifecycle. By promoting collaboration and transparency among sales, operations, and partners, Manufacturing Cloud enables manufacturers to gain a holistic view of their customers and make informed decisions. It offers actionable insights and proactive features that drive predictable business growth. Additionally, Manufacturing Cloud unifies account planning and forecasting, fostering greater transparency and collaboration across the entire manufacturing ecosystem.

Let’s consider an example of a manufacturing company that manufactures electronic devices. Using it, the company can easily track all customer activities, such as orders, inquiries, and support requests, in one centralized system. The sales team can collaborate with the operations department to ensure timely production and delivery of the devices while sharing real-time updates on customer requirements. Furthermore, by leveraging Manufacturing Cloud’s forecasting capabilities, the company can accurately predict demand, optimize inventory levels, and proactively address any potential supply chain issues. This streamlined process not only enhances customer satisfaction but also drives the company’s growth and profitability.

Here are some of the prominent features of the platform that are vital in enhancing the user experience manifolds.

The feature as the name suggests is there to assist all the involved parties in the agreements i.e. the manufacturers and the sellers/ vendors to create a comprehensive view of customer-negotiated terms and to maintain proper transparency. Users can track planned volumes and revenues alongside actual performance, enabling better decision-making. Additionally, the feature allows for customizable time-phased metrics, offering deeper insights into customer relationships and helping manufacturers align their sales strategies with customer expectations.

This feature allows manufacturers to tailor forecasts to specific customer accounts. By understanding the unique purchasing patterns and preferences of each customer, manufacturers can create more precise production plans. This targeted approach enhances customer service and ensures that manufacturers can meet specific client needs effectively.

The Community Cloud Integration feature extends the capabilities of the cloud by providing real-time visibility and digital cooperation tools to customers and channel partners. This integration reduces latency in the planning process, which in turn enhances forecast accuracy. By allowing external stakeholders to access relevant information and collaborate seamlessly, manufacturers can streamline operations and improve overall efficiency in meeting customer demands.

Manufacturing Cloud leverages advanced analytics to create accurate demand forecasts. By analyzing historical sales data, market trends, and seasonal patterns, manufacturers can predict future demand more reliably. This capability helps minimize excess inventory and reduce stockouts, ultimately leading to improved operational efficiency and customer satisfaction.

Here we have outlined the different benefits of Salesforce Manufacturing Cloud:

Salesforce Manufacturing Cloud brings different departments together to improve the collaboration and communication between them. The connected system results in improved business processes, and a smooth stream of information across all departments and supply chains. Apart from breaking down silos, Manufacturing Cloud also helps in cross-functional collaboration which reduces the chances of errors.

Let’s take an example of a manufacturing organization using Manufacturing Cloud. The organization can quickly bring together sales, services, and operations teams. This would result in easy sharing of customer information, and improved production status, resulting in everyone working on the same page.

The advanced analytics and forecasting capabilities of the Manufacturing Cloud allow organizations to make use of historical data, market trends, and customer insights to make accurate predictions. These forecasts help organizations decide about resource planning, production volumes, and sales strategies.

With Salesforce for manufacturers, companies can precisely predict the demand for their products based on historical data. This allows the manufacturer to make easy preparations to optimize production schedules, resource planning, and inventory management to meet customer demands. Also, this business prediction will help the manufacturer to minimize overstock and shortfalls.

Salesforce Manufacturing Cloud provides robust inventory management competencies, allowing manufacturers to track inventory levels, monitor stock movement, and optimize inventory management processes. Manufacturers can gain real-time visibility into inventory across multiple locations, enabling them to make data-driven decisions about stock restocking, production planning, and order fulfillment.

For example, a manufacturer using Salesforce Manufacturing Cloud can set up automated alerts when inventory levels reach the predefined limit. This ensures that timely actions are taken to replenish stock, preventing stockouts and reducing carrying costs.

Salesforce Manufacturing Cloud allows manufacturers to update contracts instantly, eradicating the need for manual paperwork and reducing administrative work. Contract changes, such as pricing updates, terms, and conditions changes, or product configurations, can be made in real time, ensuring that accurate information is accessible to all stakeholders.

For instance, a manufacturer using Salesforce Manufacturing Cloud can swiftly update contract terms for a customer. This allows them to respond fast to changing requirements or negotiate special pricing, reducing delays and improving customer satisfaction. With instant contract updates, manufacturers can improve agility, minimize discrepancies, and simplify contract management.

Salesforce Manufacturing Cloud allows manufacturers to follow leads throughout the entire sales cycle, providing valuable insights into lead performance and conversion rates. By capturing and analyzing data related to lead sources, interactions, and outcomes, manufacturers can optimize their sales and marketing strategies to improve conversion rates and increase revenue.

For example, manufacturers using Salesforce for their manufacturing companies can identify which marketing campaigns generate the most qualified leads. They can explore the conversion rates of leads generated from different channels, such as trade shows, email campaigns, or website inquiries. With this information, manufacturers can allocate their resources more effectively, focusing on the most successful lead-generation channels and maximizing their marketing efforts.

Salesforce Manufacturing Cloud enables manufacturers to streamline their service delivery processes, resulting in faster response times and improved customer satisfaction. By centralizing customer information, service requests, and case management, manufacturers can provide prompt assistance, track service progress, and ensure timely resolution of customer issues.

For instance, a manufacturer using Salesforce Manufacturing Cloud can automate service request routing, ensuring that customer inquiries are directed to the appropriate teams or technicians without delays. This reduces response times, enables faster issue resolution, and enhances customer experience. Manufacturers can also leverage historical service data to identify areas for improvement and proactively address recurring issues.

One of the key benefits of Salesforce Manufacturing Cloud is its seamless integration and compatibility with existing systems. Manufacturing companies often have a complex ecosystem of software applications and processes in place. Salesforce Manufacturing Cloud is designed to work harmoniously with these systems, ensuring a smooth transition and minimal disruption during implementation.

Whether you have existing CRM systems, ERP solutions, or other specialized manufacturing software, Salesforce Manufacturing Cloud can integrate with them effortlessly. It allows for data synchronization and exchange, enabling a unified view of your operations and customer interactions.

By integrating Salesforce Manufacturing Cloud with your existing systems, you can leverage the strengths of each platform and enhance your overall manufacturing capabilities. Data from various sources can be consolidated, providing comprehensive insights into your business processes. This compatibility ensures that you can continue using your preferred tools and workflows while gaining the benefits of Salesforce Manufacturing Cloud’s robust CRM functionalities.

Here is a step-by-step Salesforce Manufacturing Cloud implementation guide;

Setting up a sales agreement is one of the initial steps in the Manufacturing cloud implementation guide. This provides the sales team with timely access to committed and actual order volumes.

Sales agreements in the Manufacturing Cloud also help the accounts manager gain insights into custom time-phased metrics, profits, and inventory. So manufacturers can make informed decisions regarding the inventory, sales prices, and discounts to book maximum profit.

Beyond these objects and fields, Salesforce Manufacturing Cloud permits you to set up custom objects to capture any additional information.

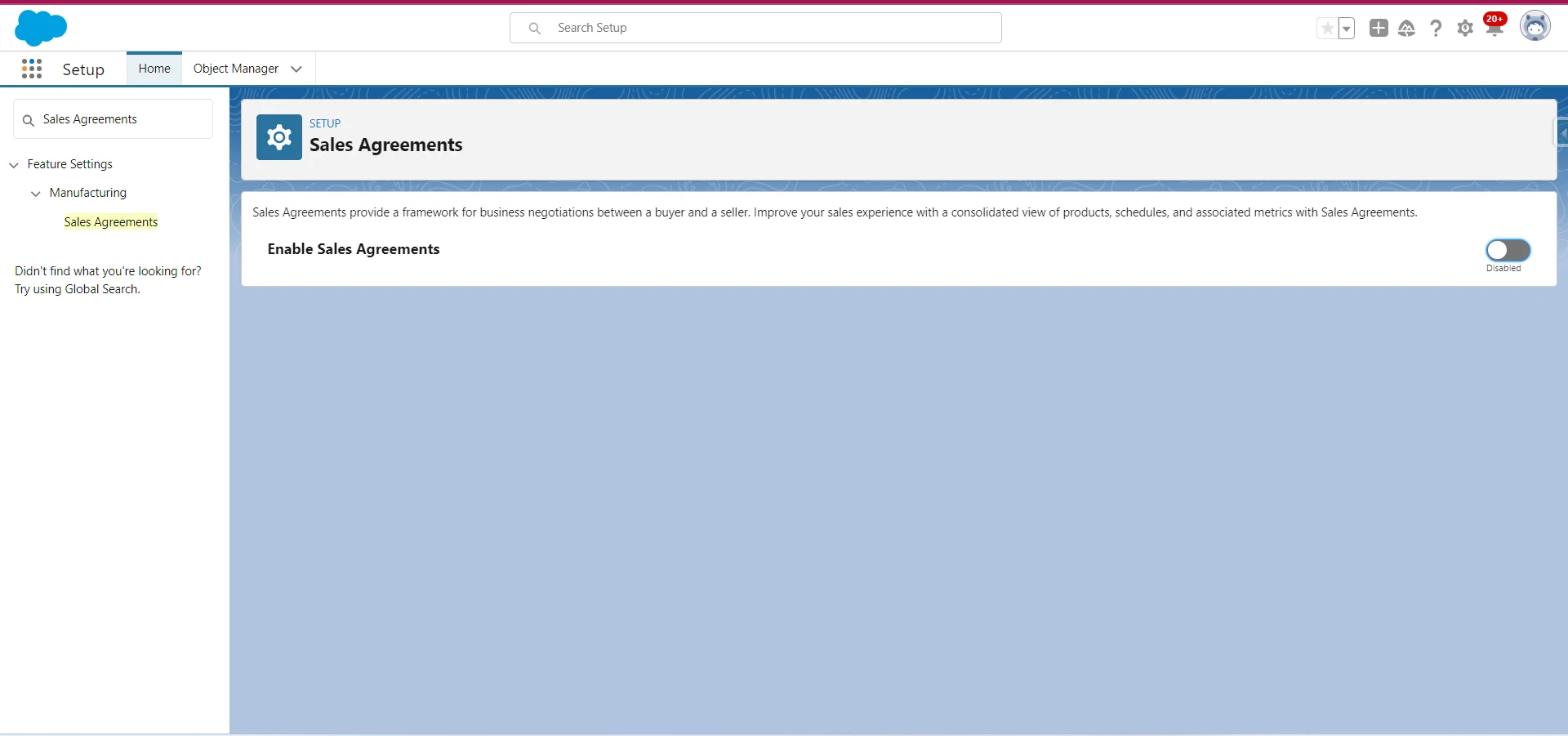

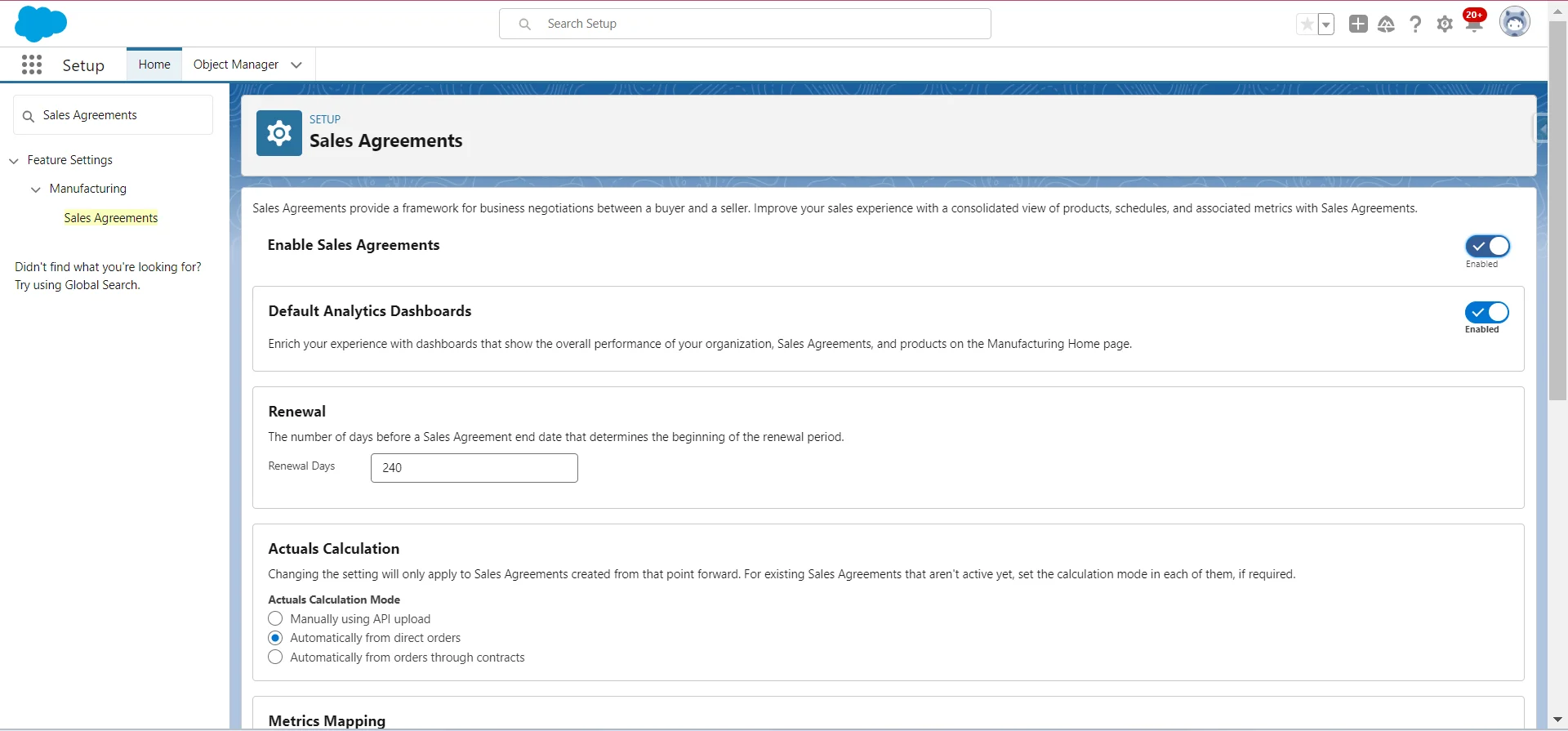

Define the sales agreement terms and conditions that both you and your customer agree upon. These terms and conditions are essential for governing sales agreements. To define sales agreement terms and conditions, first, you have to enable the sales agreement. Here is how you can do so;

Here is the different type of configurations that you can make to the Sales Agreement;

Following the successful set up of necessary objects & fields, and defining the terms, the next step would be to create a sales agreement. Here is how you can create a sales agreement in Salesforce Manufacturing Cloud;

Once you have created the sales agreement, you can easily manage the lifecycle of the agreement from the Salesforce setup menu. You can monitor the progress of the sales agreements, making necessary changes.

Salesforce Manufacturing Cloud not only helps businesses with a comprehensive overview of current business operations along with future opportunities. Here is how to enable account forecasting in Salesforce Manufacturing Cloud;

You can also set the custom field on the account object to collect the additional information that you may require.

The forecasting hierarchy presents a structure that gives you insights into the sales organization’s performance in real-time. It is used to compile forecasts for individuals, teams, and managers. So, you can see which team or region is performing well.

You can create the forecasting hierarchy by navigating through Setup > Manufacturing > Account Forecasting > Forecasting Hierarchies. From Setup, you can easily create, edit, and manage the hierarchy permissions.

Forecasting periods refer to the time for which you want to create a forecasting hierarchy. Salesforce Manufacturing Cloud enables you to set the forecasting periods from month, quarter, and year.

You can set the forecasting periods by navigating to Setup > Manufacturing > Account Forecasting > Forecasting Periods. You can create, edit, and manage forecasting periods.

Forecasting rules are used to define how forecasts are generated. You can define the rules to generate forecasts based on information such as historical sales data, market trends, or any other factor.

You can create the forecasting rules from Salesforce Manufacturing Cloud’s Setup. Navigate to Setup > Manufacturing > Account Forecasting > Forecasting Rules.

Once you define the forecasting rules, the next step would be to assign the rules to the account for which you want to forecast.

Navigate to the Account Object in Salesforce, click on the forecasting tab, and you can select the forecasting rule that you want to assign to a specific account.

Once the forecast is created successfully, it will be reviewed and approved by the appropriate account such as managers.

To review the forecast navigate to Manufacturing > Account forecasting, and select the forecast which you want to review. You can approve the forecast by clicking on the Approve.

Salesforce Manufacturing Cloud lets you generate the forecast report for each approved forecast. So you can keep track of forecast performance.

Here is how you can generate the forecast report;

Salesforce Manufacturing Cloud lets you create responsive portals where your partners can collaborate, and access knowledge articles, generate forecast reports, and more.

Salesforce Experience Cloud is a powerful solution that helps manufacturers create customizable and responsive partner portals. Here is how manufacturers can create partner portals;

Here is a brief overview of the challenges faced by businesses when implementing Manufacturing Cloud Salesforce:

Implementing Salesforce Manufacturing Cloud can present challenges in obtaining a comprehensive and consistent understanding of customers and their needs. This means that manufacturers may struggle to gather and analyze all the relevant information about their customers, such as their preferences, purchase history, and specific requirements. Without a holistic view, it becomes difficult to personalize products, improve customer satisfaction, and make informed business decisions.

A challenge often encountered is the limited insight into the performance and quality of partner organizations within the supply chain. Manufacturers rely on various partners, such as suppliers and distributors, to facilitate their operations. However, without proper visibility into these channels, it becomes challenging to assess their effectiveness, identify areas for improvement, and ensure consistent quality standards throughout the supply chain.

Inaccurate revenue and production forecasts pose a significant challenge in Salesforce Manufacturing Cloud implementation. Forecasts are essential for planning resources and operations, but if they do not align with actual demand and sales, it can lead to inefficiencies like overstocking or stockouts. Having accurate forecasts is crucial for optimizing resources and meeting customer demands effectively.

Adapting to changes quickly and efficiently is crucial in today’s dynamic business environment. However, implementing Salesforce Manufacturing Cloud may introduce obstacles in terms of flexibility and adaptability. If the system lacks the necessary tools and processes to accommodate changes smoothly, manufacturers may find it challenging to promptly adjust strategies, operations, and customer engagement approaches.

Integrating existing data systems and migrating data to Salesforce Manufacturing Cloud can be a complex process. Manufacturers often have multiple data sources and legacy systems that need to be seamlessly integrated into the new platform. This challenge requires careful planning, data mapping, and validation to ensure a smooth transition without compromising data integrity or causing disruptions in operations.

Introducing a new system like Salesforce Manufacturing Cloud requires users to learn and adapt to the new tools and processes. Manufacturers may face challenges in user adoption and training, especially if employees are accustomed to different systems or resistant to change. Adequate training and change management strategies are necessary to ensure a successful implementation of Salesforce and maximize the benefits of the platform.

Want to implement the Salesforce Manufacturing Cloud? Here we have shared the best practices that you can follow to ensure successful implementation:

The first and foremost important practice is to ensure you have a good understanding of the goals and objectives that you want to achieve with Salesforce Manufacturing Cloud. This will help keep your implementation focused and aligned with your organization’s needs.

Assess your current processes, data, and systems to understand their readiness for implementing Salesforce Manufacturing Cloud. Engage key stakeholders from sales, operations, IT, and finance departments—secure support from senior leaders to drive the implementation and overcome any challenges.

Design a data structure that can adapt and grow with your manufacturing processes. Consider how different elements, like products, customers, and orders, relate to each other. Plan for data integration and migration from existing systems to Salesforce Manufacturing Cloud, ensuring accuracy and consistency.

Customize and configure Salesforce Manufacturing Cloud to meet your specific requirements. Adjust workflows, user interfaces, and automation rules to align with your manufacturing processes. Take advantage of industry-specific features provided by Manufacturing Cloud.

Invest in user adoption and training programs to ensure that all users understand and utilize Salesforce Manufacturing Cloud effectively. Provide training sessions, documentation, and ongoing support to help users embrace the new system. Encourage feedback and address any concerns promptly.

Implement strong data governance processes to maintain data integrity and consistency. Define data standards, validation rules, and workflows. Regularly review and clean up data to prevent duplicates or outdated information.

Salesforce Manufacturing Cloud deals with sensitive customer data and operation data. Therefore, it is a must to comply with all the security measures and compliance supported by the platform. The sensitive information should be protected with data encryption controls, and compliance certifications (e.g., GDPR, HIPAA).

Utilize Salesforce Manufacturing Cloud’s capabilities to improve collaboration with partners and customers. Enable seamless communication, data sharing, and visibility across the supply chain. Use partner portals and customer communities to enhance collaboration and efficiency.

The manufacturing industry is projected to reach US$2.0tn in 2024. With an annual compound growth rate of 1.24% is expected (CAGR 2024–2029). (Source; Statista)

This growth led to increased competition in the industry. The number of manufacturing enterprises is expected to amount to 460.70k in 2023 according to Statista.

Embracing the technological advancements offered by Salesforce Manufacturing Cloud can help you find the way through the competition. Features such as unified operations, inventory management, lead tracking, and conversion, stands out as the best partner for manufacturing enterprises in their growth.

Here are a few reasons that make Manufacturing Cloud the best choice for the manufacturing industry;

Transform Your Manufacturing Operations Using AI Agents by Agentforce

Reduction in excess inventory

Reduction in manual reporting and data entry

Reduction in lead conversion time

Salesforce Manufacturing Cloud offers flexible pricing models to meet the needs of different types of businesses. Each plan includes distinct features depending on the business size, ensuring you make the right pricing choice.

Manufacturing Cloud – Sales: This plan’s pricing starts at USD 250/user/month. It offers Sales Cloud functionalities such as viewing net-new opportunities, run-rate agreements, and demand forecasts.

Manufacturing Cloud – Service: This plan starts at USD 250/user/month and offers Service Cloud functionalities such as a Service Forecasting Framework, Digital Process Automation, and more.

Manufacturing Cloud – Sales and Service: This plan’s pricing starts at USD 450/user/month. It offers the combined capabilities of both Sales Cloud and Service Cloud pricing plans.

Then there are the Einstein Editions for cloud users. These editions provide advanced AI capabilities for sales and service, enhancing automation and insights. The plans Einstein 1 for Sales and Einstein 1 for Service are billed annually and priced at USD 650/user/month, respectively.

The Salesforce Manufacturing Cloud is an indispensable tool for organizations in the manufacturing industry. It enables organizations to connect their sales, and operation teams to gain improved visibility into their production processes. It generates a single source of truth for all manufacturing data such as orders, inventory, customers, production schedules, and so on eliminating the data silos.

Impressed by the benefits of Salesforce Manufacturing Cloud? Looking for a trusted Salesforce implementation partner to help you implement Manufacturing Cloud customized to your unique business needs? Cyntexa as a Salesforce partner is here to help you with your vision. We have a team of more than 300+ Salesforce professionals to help you supercharge your business growth with the Salesforce platform.

Don’t Worry, We Got You Covered!

Get The Expert curated eGuide straight to your inbox and get going with the Salesforce Excellence.

AUTHOR

Head of Growth And Strategy

Tanushri heads Growth and Strategy at Cyntexa, with over 6 years of experience in sales and marketing. She specializes in aligning go-to-market teams, scaling revenue operations, and building structured, tech-enabled growth plans. Tanushri also advises businesses on Salesforce, ServiceNow, AWS and Google Cloud adoption, ensuring each strategy is execution-ready, future-proof, and tailored to the organization’s maturity and growth goals.

Join Our Newsletter. Get Your Daily Dose Of Search Know-How

Salesforce Manufacturing Cloud can be easily integrated with other Salesforce products such as Sales Cloud, and Service Cloud. Apart from these, it can also be integrated with ERP and SaaS applications with the help of API-driven integrations.

The Salesforce Manufacturing Cloud data model is designed to provide users with relevant objects and fields to create & manage sales agreements, business negotiations & planning, account forecasts, and so on.

Yes, Manufacturing Cloud can be customized to meet specific business needs. It has objects, features, and tools built to meet the specific needs of the manufacturing industry.

Become a next-gen business with us.

Tell us about your idea and we’ll bring it to life. Schedule a FREE consultation today.

Looking for a new career?

View job openings

By submitting, you consent to Cyntexa processing your information in accordance with our Privacy Policy . We take your privacy seriously; opt out of email updates at any time.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Looking for a new career?

View job openings